South West England

- 01823 443898

Northern Ireland

- 02840 623566

Air monitoring and fibre counting are the procedures used to determine the presence of asbestos fibres within the air within a specific test location. It is an essential practice in the management of asbestos, a hazardous fibre that was once commonly used in construction materials. The inhalation of asbestos fibres can cause serious health problems. As a result, it is essential to monitor the fibre levels in the air in areas where asbestos may be present, such as during removal or remediation work.

At G&L, we understand the importance of air monitoring in protecting the health and safety of individuals within the built environment. Our experienced analysts work under our UKAS accreditation to carry out air monitoring and fibre counting in accordance with the HSE document ‘Asbestos: The Analysts’ Guide.’ We offer a comprehensive range of air monitoring services for a variety of reasons. We may visit a domestic property to carry out a single test to reassure the owner than a particular room has not been contaminated, or we may visit a large industrial site to carry out testing over several weeks to closely monitor a large scale removal project.

We offer several types of air monitoring, including background monitoring, leak monitoring, reassurance monitoring, 4-stage clearance monitoring, and personal monitoring.

This type of air monitoring is carried out before any asbestos removal work begins. It helps to establish whether there is already an existing problem and to establish a baseline ambient level of asbestos fibres in the air. The information gathered from background monitoring is helpful for future leak monitoring and clearance monitoring.

This type of air monitoring is carried out during asbestos removal work, outside the asbestos enclosure. It helps to ensure that the control measures used during the removal work are adequate and that asbestos fibres are not contaminating the surrounding area. A high result from leak monitoring can give an early warning that asbestos fibres are escaping from the enclosure, which can be addressed before further contamination occurs.

This type of air monitoring can be carried out for a variety of reasons such as, after non-licensable asbestos removal, a breach in an asbestos enclosure, or the discovery of damaged asbestos. Reassurance monitoring provides reassurance that the area is safe for reoccupation and that any asbestos fibres present have been removed or controlled to a safe level.

Our team carries out personal monitoring by using a small sampling pump to assess the levels of airborne asbestos fibres present in the breathing zone of the operative. This allows us to assess the exposure levels of the operative to ensure they are adequately protected and the control measures in place are suitable and effective in preventing the inhalation of asbestos fibres. Our comprehensive personal monitoring service helps to create a safer working environment for all individuals involved in asbestos-related work.

This type of air monitoring is required after licensed asbestos removal work. The 4-stage clearance process involves a preliminary check of the site conditions, a thorough visual inspection inside the enclosure or work area, air monitoring and a final assessment after the enclosure or work area has been dismantled. Only after a successful visual inspection and clearance monitoring can an area be classed as safe to re-enter. Four-stage clearance monitoring can only be conducted by UKAS accredited analytical companies, ensuring that all stages of the process are conducted to the highest standards.

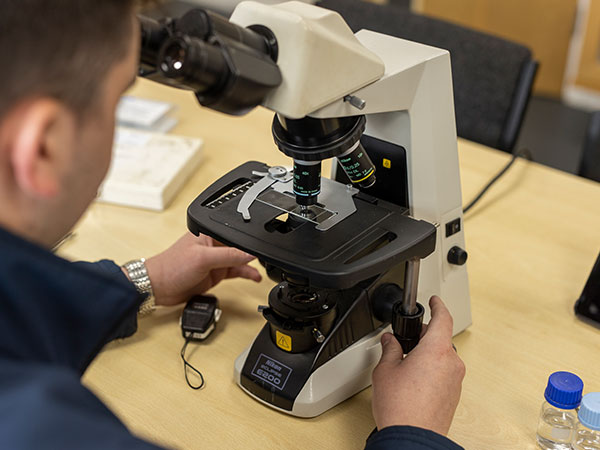

Our mobile laboratories are all equipped with state-of-the-art equipment and technology, enabling us to carry out fibre counting on site, immediately following air sampling and providing clients with instant results. Our site reports are also electronically produced with colour photos throughout and printed on-site and issued electronically, ensuring a quick turnaround time and prompt action if required.

Alternative fibre analysis procedures such as Scanning Electron Microscopy (SEM) or Transmission Electron Microscopy (TEM) can also be organised by G&L at your request.

At G&L, we pride ourselves on our people-first approach and unwavering commitment to excellence. Our highly trained and experienced team ensures top-notch quality and professionalism in every project, positioning ourselves as your trusted partner in training and asbestos. With our comprehensive range of services and unmatched expertise, you can be confident that we will make a meaningful difference in creating a safer built environment for all.

If you would like to request an Air Test please download our Air Test Booking Form which can be completed electronically and then emailed to airtests@gnl.org.uk.

We will then process your request and email your confirmation.

Contact us today, and our friendly team will be happy to assist you with any questions you may have.

We are accredited / certificated for:

Our UKAS accreditation is limited to those activities described on our UKAS schedule of accreditation.

Click here to find out more about all our accreditations / certifications.